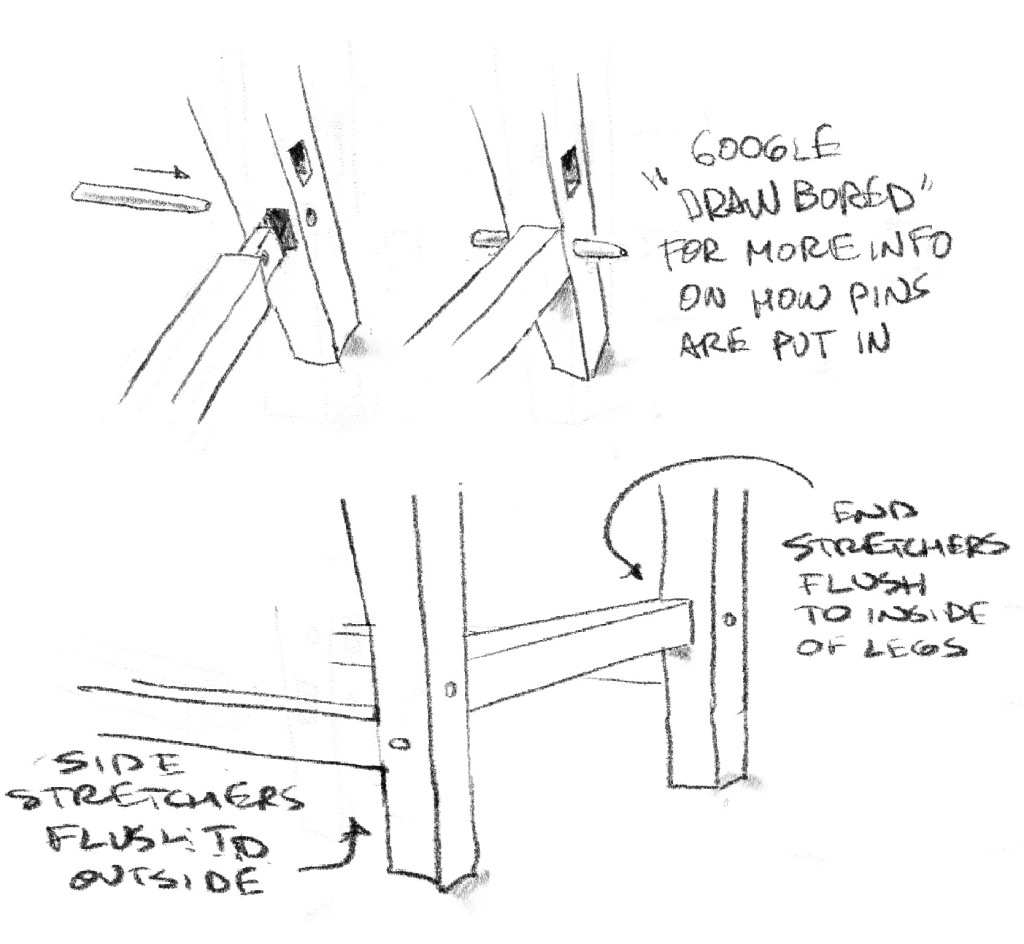

The mortises of the stretchers are off-set vertically to preserve strength in the leg. If the leg were thicker, it would be possible to have them on the same level. The side stretcher is flush to the outside while the end stretcher is flush to the inside.

The truss assembly worried me a lot when I was mentally rehearsing this build. The vertical trusses are straightforward – they can be measured and cut while the stool is dry fitted together. If their length is a tiny bit off, it’s only cosmetic. The diagonals are another story. They’re trickier to fit and if the length is off by the tiniest amount, it’ll throw the stool slightly out of square. With 8 diagonal struts, there’s a real danger that tiny errors could compound, only becoming apparent during glue up as the pins are being driven home. At that point I was feeling stumped.

Geoffrey Killen mades observation about EA2476 on pg 44 of Egyptian Woodworking and Furniture “Some of these (lattice braces) are tenoned into mortises in the horizontal elements while others are simply wedged into position.” I’m unsure exactly what he meant by “wedged” because the angle of the diagonals is too acute for them to be just pushed into position and stuck there but it got me thinking…

Disclaimer #4 – without an x-ray I can’t be certain but I feel the following is reasonable speculation.

I’ve seen photos of cabinets and stools with dowelled lattice work and it appears the bottoms of the diagonal trusses are just pressed into notches. Several of the ancient lattice stools have their diagonal trusses connecting to the stretcher at a peculiarly uniform distance from the leg. I think the gap might be there so that a stub tenon can be slid into a mortise. In use, there’s a tendency to bump your heels against the stool’s sides and I think this tiny tenon will do a lot to keep the diagonals in place.

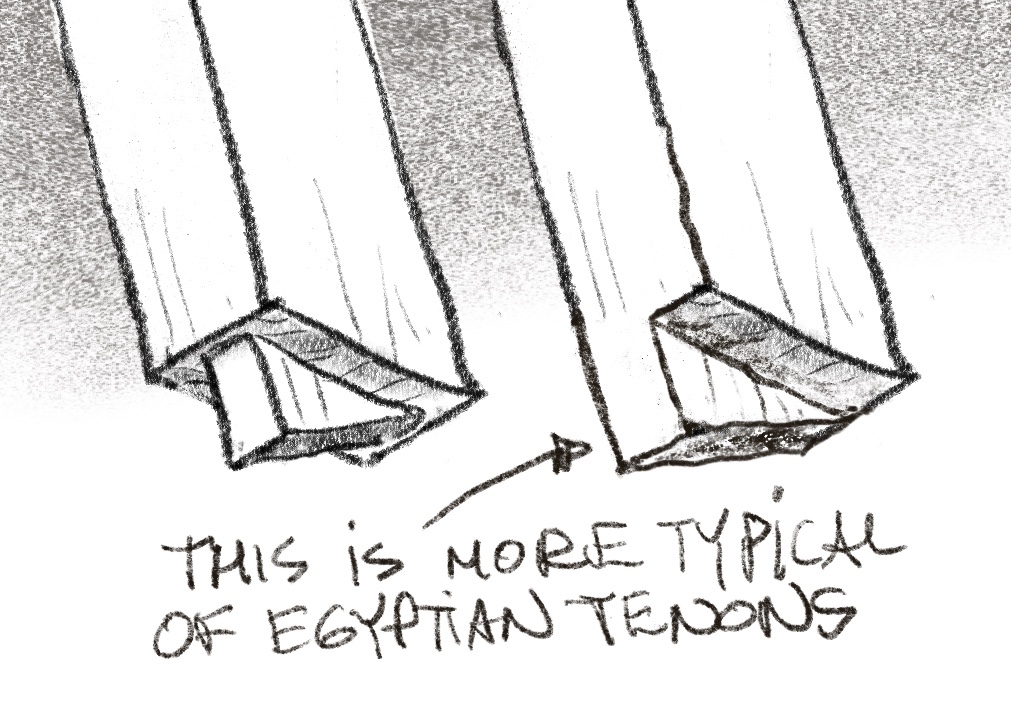

Edit: the centred tenon I used here probably isn’t perfectly accurate. It would be easier to execute, stronger and better situated upon the supporting rail if it were just cut away from one side, which would be in keeping with the tenons I’ve seen in the other pieces I’ve copied….except where a centred tenon is explicitly called for, as in the case of legs joining into seats.

So here it is glued and pinned, with the vertical trusses in place.

With it now perfectly solid and square, I was able to leisurely tweak all the diagonals for a good press fit without introducing any excessive strain on the structure.

This was important because they work in compression, and in opposition to each other. I glued them in with gesso. There are x-rays of joinery inside an Egyptian chair on the Brooklyn Museum site that used a hide glue/calcium powder mixture (gesso) as a gap filling glue. With a subsequent layer of gesso and paint overall, they feel pretty secure.

Finished…

Now we finally get to see how EA2476 would’ve looked as it left an African workshop more than three millennia ago.

It feels very sturdy yet it’s pliable enough to settle flat on an uneven floor without making any creaking sounds. I’m a little over 5’10” and feel it was made for someone my height or slightly taller. I’d be curious to know if 38cm is a standard height for this type of stool.

Stay safe and look after each other.

Paul Bouchard